Arctic, or ice classed, cargo ships is a wide definition, and the ship size range covers all sizes of the ships. In the European area these ship types are required only in Baltic navigation and arctic areas, e.g. Greenland. The future expectation is that shipping activity in the Arctic regions will grow rapidly due to the large reserves of oil, gas and other natural resources in Russian Arctic and since the most economical way to export these resources is by sea. This means that more and more ship owners will have to obtain ships with high ice class to ensure safe and year round operation and this is also why the operation profile is selected to adapt that.

High ice class generally means higher fuel consumption, and thus emissions. State of the art Ice classed ships are designed and built mostly by the requirements of applicable rules, which require additional engine power to be installed. Ice going ships planned for operation in heavy ice conditions may utilize already well proven solution called Double Acting ship. With this ship type the fuel consumption can be about 50% lower compared to majority of ice-going ships in use, mainly due to the possibility of optimizing the bow for open water characteristics. As this kind of ship is significantly better compared to traditional ones, such was selected to be the baseline vessel.

Baseline vessel, MS Norilskiy Nickel

MS Norilskiy Nickel, an arctic container vessel built under NB 505 at STX Finland in Helsinki, was delivered on 11 April 2006 to the Russian MMC Norilsk Nickel, one of the world´s leading metallurgic companies.

MS Norilskiy Nickel was a prototype based on the double-acting ship concept developed by STX Finland. Double-acting ship concept means that when crossing waters in heavy ice conditions, the vessel moves stern-first to break its way through thick ice and when operating in light ice conditions or open water the vessel sails traditionally, bow-first. This double-acting vessel design therefore significantly improves operational efficiency.

Norilskiy Nickel was the world’s first commercial vessel, which can operate independently year-around in Siberia without ice-breaker assistance. It can move 3 knots in 1.5 m thick first year ice field. The prototype vessel and her four sister vessels have now been operating autonomously year round in this area for several years.

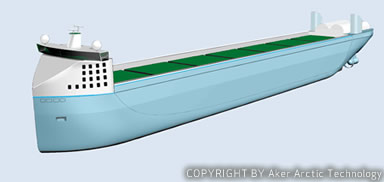

2025/2050 Ship Concept, 2000+ TEU full container vessel

2000 TEU full container vessel for trans-arctic operation via Northern Sea Route with LNG dual fuel machinery and waste heat recovery technologies.

For arctic ships a large share of the energy consumption is needed for propulsion, heating and de-icing systems. Energy demand will be reduced and the efficiency improved by applying heat recovery systems, new material, paints, new types of insulation and lower requirements for ballast water capacity. Further the demand can be reduced by efficient propulsion systems for Double Acting ships allowing about half of the propulsion power in ice breaking operation compared to traditional ships.

Consumption and emission reductions compared to baseline vessel:

- Units per annual transported amount of TEU

- Fuel consumption: -47%

- CO2: -63% + CH4 eq: -62%

- NOx: -96%

- SOx: -99%

- PMa: -99%