A ship can be considered as a mobile power plant. Whilst the propulsion system is usually the largest demand on

the ship, the majority of the ship’s other loads are distributed around the vessel. This report is concerned with the

technologies available to get energy from one part of the ship to another, and looks at the different advances in

mechanical and electrical storage mechanisms to allow machinery, hotel loads and other energy consumers to be

provided with energy from the ship’s prime movers. The most common marine energy distribution system is electrical,

so these technologies are covered in the most depth for this report.

Electrical energy is high grade, and as such can be utilized highly efficiently compared with conventional

mechanical or thermal means. Electric motors for instance are typically ~95% efficient at converting energy from

electrical to kinetic, and electrical energy can be transported easily via the use of cables around the vessel, with

much lower losses than a mechanical system such as the use of shafts and gearboxes or hydraulics. For the reasons of

efficiency, size and flexibility of design, electrification of shipping promises to be a key area of interest in the

future to lower emissions.

In the next section the various components which make up a typical marine electrical system are defined. These

components are combined into electric power conversion technologies. In the last section the power conversion

technologies are combined to applications.

In order to be useful, electrical power in a ship must be created, controlled, directed and transformed via the

use of power conversion technologies, so it can be used in the relevant loads required, whether they be motors for

propulsion, deck machinery or pumps, or highly sensitive electronics for control systems. Efficiency, electrical

quality (distortion), size and safety all play a part in the electrical requirements of components, and the power

grid present on all modern vessels have multiple power converters onboard which exist to perform supply electrical

power in the correct form, to where it is needed, and these include the following main technologies:

- Transformers

- Semiconductors

- Rectifiers

- Choppers

- Filters

- Control techniques

- Electrical storage

Typically the demands of any electrical component vary by a significant amount based on its function. For this

reason electrical system design concentrates on a designing a suitable conversion infrastructure for a vessel, which

is designed to cope with the major loads such as propulsion, whilst maintaining sufficient capacity and capability to

deal with typical operational requirements of a vessel, as well as leaving headroom for future upgrades. As these

requirements vary by a large amount between different vessel types, electrical systems are usually tailored made to

the vessel type during the design phase, and thus a standard configuration is not possible.

Power converters use various components to vary electrical energy, such as the conversion of AC to DC and DC to

AC, varying the voltage, current or frequency of a source and controlling the flow of energy.

Power Conversion Applications

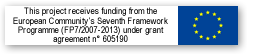

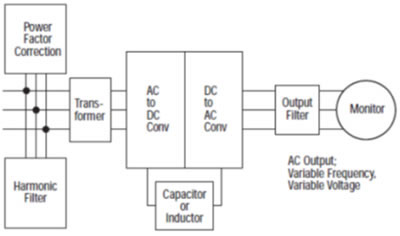

Figure 1 - Variable frequency drive schematic

Figure 1 - Variable frequency drive schematic

A typical power conversion application is the variable speed drive, as shown in Figure 1. This allows the

hook-up of an electric motor to a power source, and gives the ability to finely control the motor parameters such as

speed and torque, even if the source is providing variable and unpredictable electrical energy, which is typical in

complex grid applications with large numbers of un-coordinated consumers, such as a ship. This allows the efficient,

accurate and smooth operation of critical loads such as electrical propulsion, and extends the mechanical life of

these components. Drives can allow the use of electrical energy to assist in braking, and in some cases, energy

recovery from this. Drives also offer considerable efficiency boosts when operating motors at less than full power,

particularly in the case of variable torque loads, such as the propulsor, and constant torque loads, such as air

compressors and conveyors.

Drives, like a lot of power conversion equipment, have a number of power electronics and other conversion

equipment like filters, rectifiers, inverters and transformers within.

Another power conversion application with a high relevance to the marine industry is the UPS (Uninterruptible

Power Supply). Often used in critical systems, the UPS ensures that critical components on the grid can still receive

power even when the main system has a fault. Technology advances in this area can mean smaller, more resilient and

tolerant UPSs can be developed for use within the marine industry.

Figure 2 - Common variable frequency drive configurations

Figure 2 - Common variable frequency drive configurations

As with all conversion of energy, losses are inevitable, and technologies are under investigation in these

areas to improve their efficiency. Power electronics are the key components in increasing the efficiency, energy

density and compatibility in power conversion applications, and make up a significant part of research and

development activities in this electrical sector. In particular, switches such as transistors are used frequently in

power conversion, and different technologies at varying stages of maturity are available to industry. Fast switching

apparatus is advantageous to devices that require fast responses to load changes, whilst power dense apparatus is

suitable for managing large load changes.

By way of example in the marine industry, drives are used extensively in the control of propulsion, and the

varying requirements of main propulsion compared with tunnel thrusters for example drive design decisions in this

area, and typical configurations for marine vessels are shown in Figure 2, with the most common being the 6 pulse

example, using IGBTs (Insulated Gate Bipolar Transistors).

Electrical power needs to flow around the ship, and this usually involves a lot of wire, cabling and

switchboards taking the power from the point where it is produced to the point where it is consumed.

Losses in the distribution system can be minimized by the use of higher voltages, but a balance between

minimizing losses and safe operation must also be struck to ensure that in the case of faults, personnel and

safety-critical equipment is safe. Electrical systems also typically need suitable materials which are conductive,

and the cost in terms of materials and weight to electrical systems can be significant, particularly in the case of

copper.

Superconducting cabling is being investigated for use in marine vessels to provide an ultra-low impedance path

between the primary generator and the primary propulsion consumer in the case of electric or hybrid propulsion; the

area in which the distribution system typically sees the largest losses.

Batteries

Rechargeable batteries play an important role in our life and many daily chores would be unthinkable without

the ability to recharge an empty battery. Points of interest are specific energy, years of service life, load

characteristics, safety, price, self-discharge, environmental issues, maintenance requirements, and disposal.

Electrical energy is hard to store, compared with chemical energy or even thermal energy for instance.

However, because of the high efficiency of electrical systems compared with more conventional mechanical systems,

the ability to store energy greatly increases the resulting performance and operational parameters of an electrical

system, as it allows the size of the generation capacity of the vessel to be closer to the mean consumption of the

vessel, rather than the peak consumption. For the small amount of time that a vessel has its highest energy demand,

it’s needs are far better suited by the use of efficient stored energy rather than producing it all on demand.

Optimizing energy storage for a vessel could result in a significantly smaller prime mover, with all the benefits of

reduced emissions, weight and fuel burn, and offers the greatest single point of improvement on the current state of

the art electrical technology roadmap.

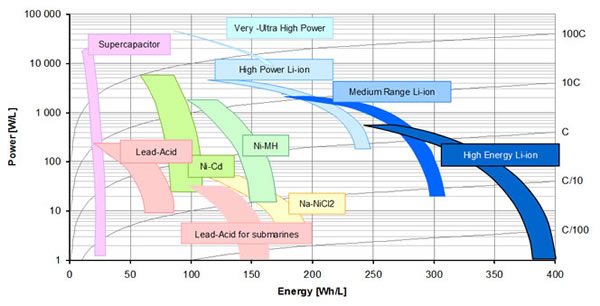

There are many technologies on the market for batteries. But considering the performances in term of power and

energy for all these applications, Lithium battery technologies are proposed because it is presently the best

performing battery technology in terms of specific mass and volume. Cells can be designed for high energy and low

current application for long discharge applications as well as for very high power pulse application where it can

almost match the performances of super-capacitors.

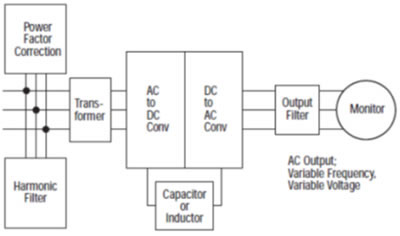

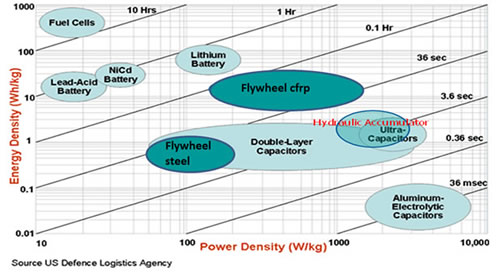

Figure 3 - Ragone chart: energy vs power density

Figure 3 - Ragone chart: energy vs power density

Conventional lead-acid battery technology could not deliver high power easily, or by dividing full power on a

large number of batteries in parallel. In that case weight and volume were not optimized.

One of the benefits will be for units that normally run at relatively low powers compared to their rating, but

need to be capable of running at significantly higher powers for short periods of time. Therefore, high power

batteries can help to reduce the peak electrical loading allowing the use of smaller distribution system.

Distribution system will be sized based on low power operation.

Figure 3 shows the advantages of different electrical energy storage technologies, including batteries and

super capacitors.

A useful analogy for interpreting this graph is to think of a battery like a watering-can, and electrical

energy as the water. High power technologies have extremely large spouts but a small storage volume, and as a result

can provide a lot of energy for a brief amount of time.

High energy technologies have large storage volumes, but small spouts, and can provide a trickle of energy for

a significant amount of time. Li-ion batteries at the moment provide the best of both worlds, providing a reasonable

power whilst being able to contain a reasonable amount of energy, and as such are a key area of state-of-the-art

investigation.

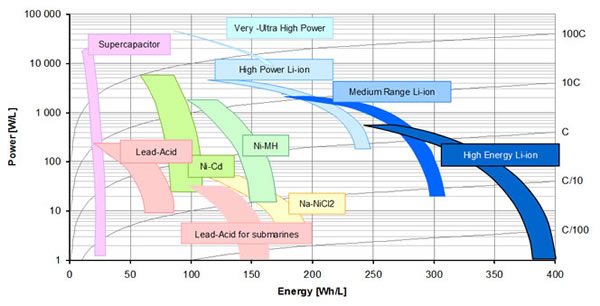

Figure 4 - Ragone Diagram - Flywheels versus electrical technologies

Figure 4 - Ragone Diagram - Flywheels versus electrical technologies

Super capacitors

The super capacitor, also known as ultra capacitor or double-layer capacitor differs from a regular capacitor

in that it has a very high capacitance. A capacitor stores energy by means of a static charge as opposed to an

electrochemical reaction.

Applying a voltage differential on the positive and negative plates charges the capacitor. These devices are

shown in Figure 6 and in terms of a marine vessel, super capacitors could offer significant improvements in terms of

meeting peak loads, particularly on motorized loads such as deck winches or even certain types of propulsion, which

may see a very high instantaneous peak load when starting or taking the initial strain but a relatively modest mean

load.

Where prime movers are sized to meet these peak loads for certain operations, the use of super capacitors can

also assist with the use of energy storage with reducing the size of electrical infrastructure onboard.

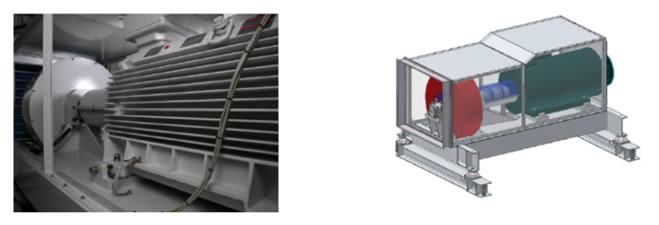

Flywheel energy storage system

A flywheel stores energy as rotational energy and can be made of steel or fiber reinforced material, in

general CFRP (Carbon Fiber Reinforced Plastic) or carbon composite. The storage capacity depends strongly on the

choice of material.

Figure 5 - Flywheel example

Figure 5 - Flywheel example

Compared to steel, the light and strong composite materials enable a considerable increase of the storage

capacity. In general it can be stated that carbon composite compared to steel flywheels enable a volume energy

density that can be about 3 times higher and a mass energy density that can be about 9 times higher.

This is due to the lower mass density of carbon composite (about 3 times less than steel) and the much higher

speeds that can be applied for carbon composite (about 4 times more than for steel).

Flywheels are capable to withstand high and frequent load and unload torques enabling high charge and

discharge powers and long life time, respectively cycle life. This makes them very attractive for applications with

frequent and high power demands.

They are also highly efficient (~90%-~95%) and low maintenance, and can provide significant amounts of energy

compared with electrical technologies, although they have a far higher self-discharge rate.

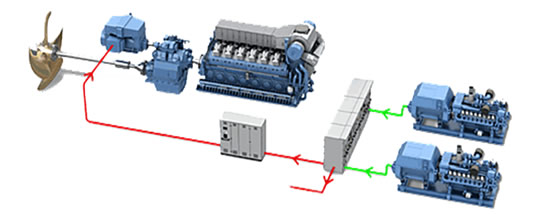

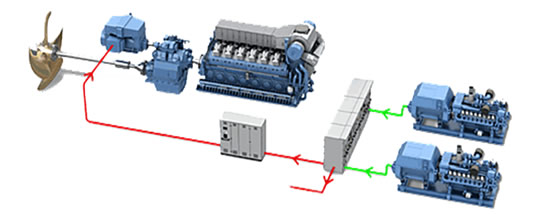

Figure 6 - An Example Hybrid topology

Figure 6 - An Example Hybrid topology

The electrification and use of hybrid propulsion in shipping is seen as a significant opportunity to reduce emissions in the

industry, and many different options are becoming apparent for the most optimal choice of prime movers, generators, shafts and motors.

For some vessels, a direct connection from the propeller to the prime mover via a shaft will produce the most efficient operational

profile for the vessel, whilst for others, the reduction of mechanical losses through the use of an electrical distribution system coupled

with the flexibility that the electrical system affords designers, means that several hybrid options are available.

The control of such a system to manage the optimal balance of electrical and mechanical energy in the system also offers significant

benefits with regard to the sizing of the prime movers, and done properly, allows the size to more closely reflect the mean power usage

rather than the worst case power usage as per current design methodology, and allows the prime movers to operate constantly in their most

optimal range as a result. There are a huge range of hybrid designs which offer different advantages to different vessel types with different

operating profiles. The control challenges within this type of system are large, as are the potential efficiency gains.